STEP 1:

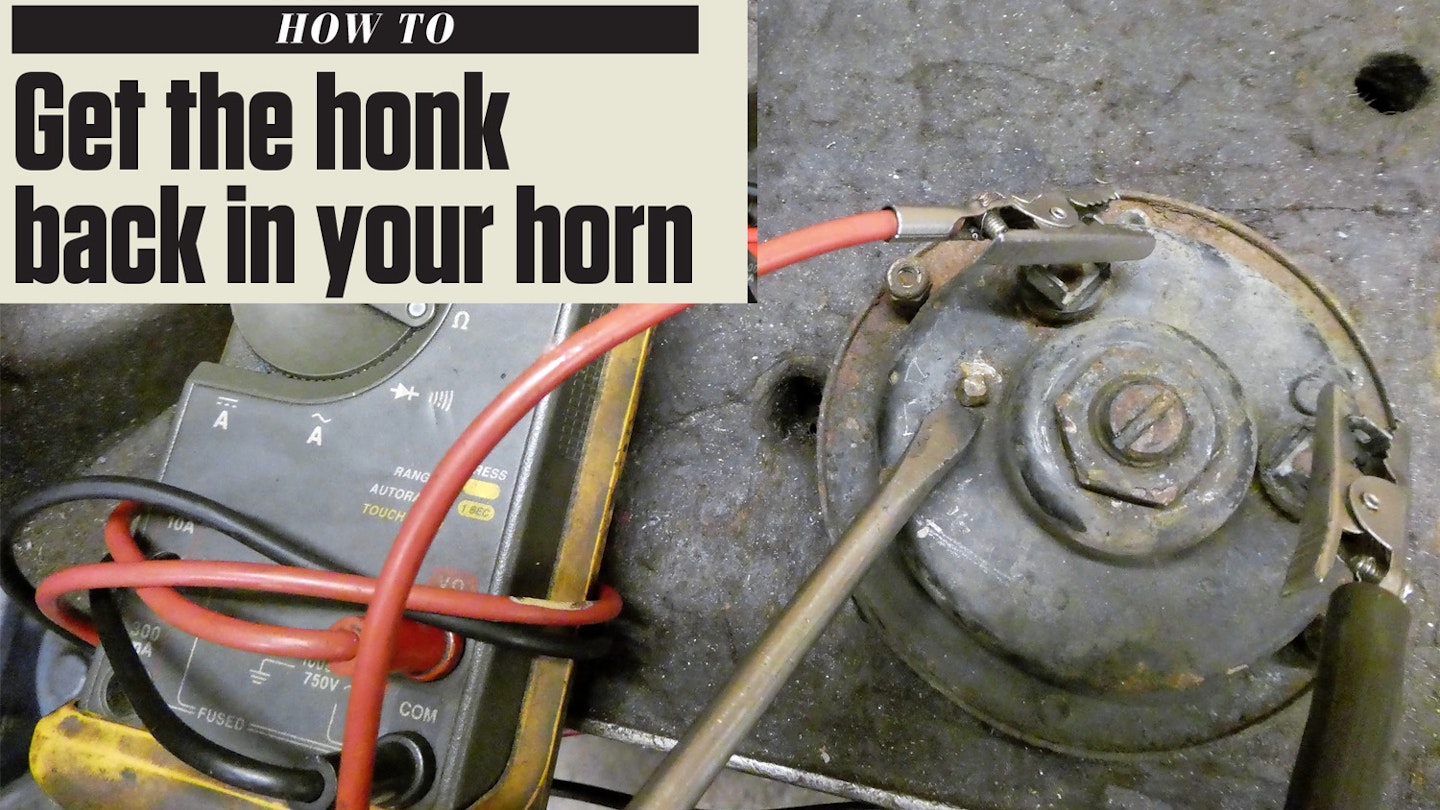

You should get continuity across the horn terminals; if not, fiddle with the adjusters. There are contact breaker points inside and the adjuster may be holding them open.

STEP 2:

The coil inside is sturdy and it gets used so infrequently that it’s unlikely to fail. The coil inside is sturdy and it gets used so infrequently that it’s unlikely to fail. If adjustment doesn’t help, it’s likely that the points are corroded – in order to access them, you’ll need to drill out the rivets.

STEP 3:

Pressing the horn button completes a circuit, energising a magnet that draws in the metal piston. As it moves, it opensthe points, cutting the magnet so it springs back and starts again.

STEP 4:

Give the points a good clean up, check them with the meter and then reassemble using (Loctited) screws orrivets. As long as there’s continuity, it should work – but you will need to readjust it.